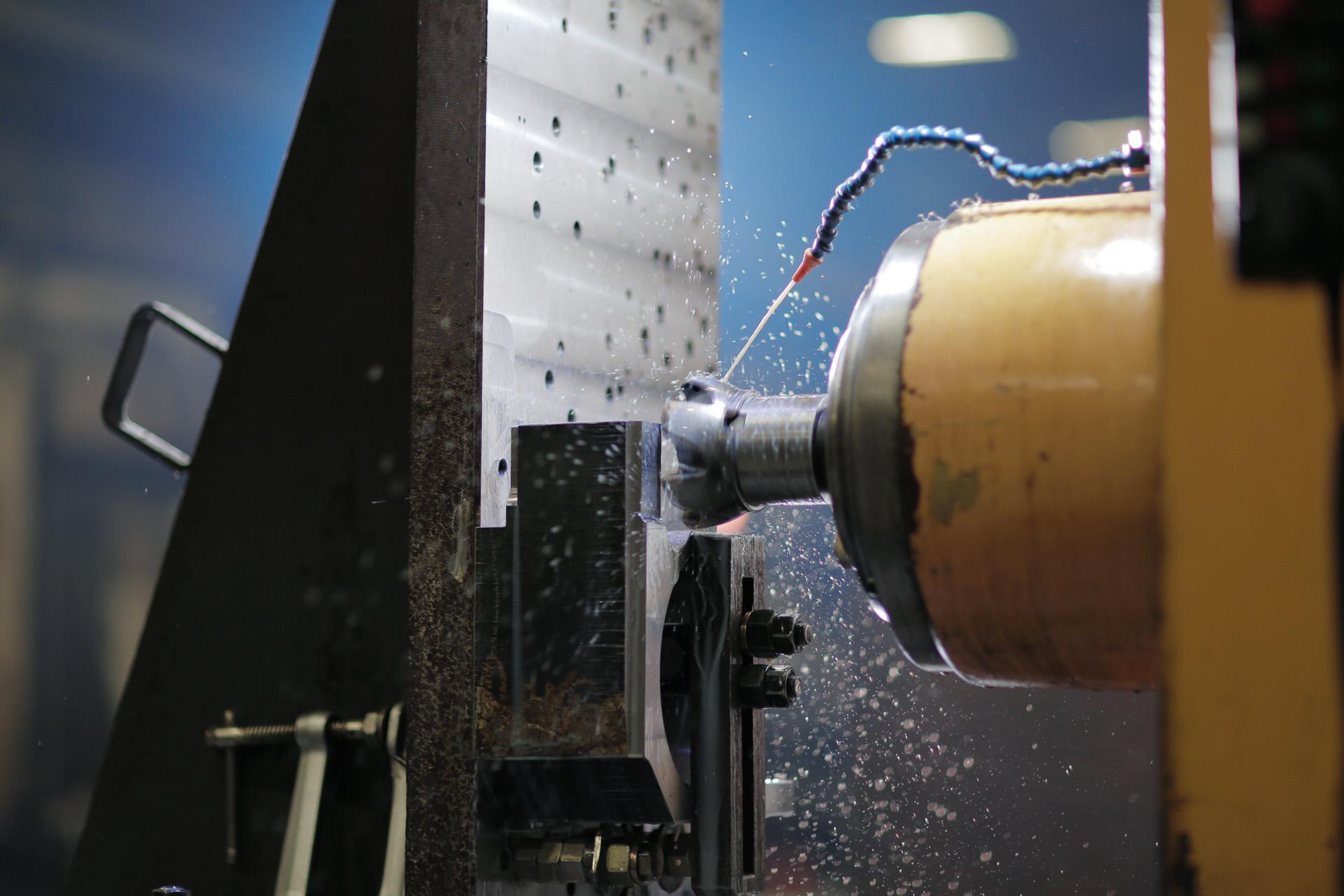

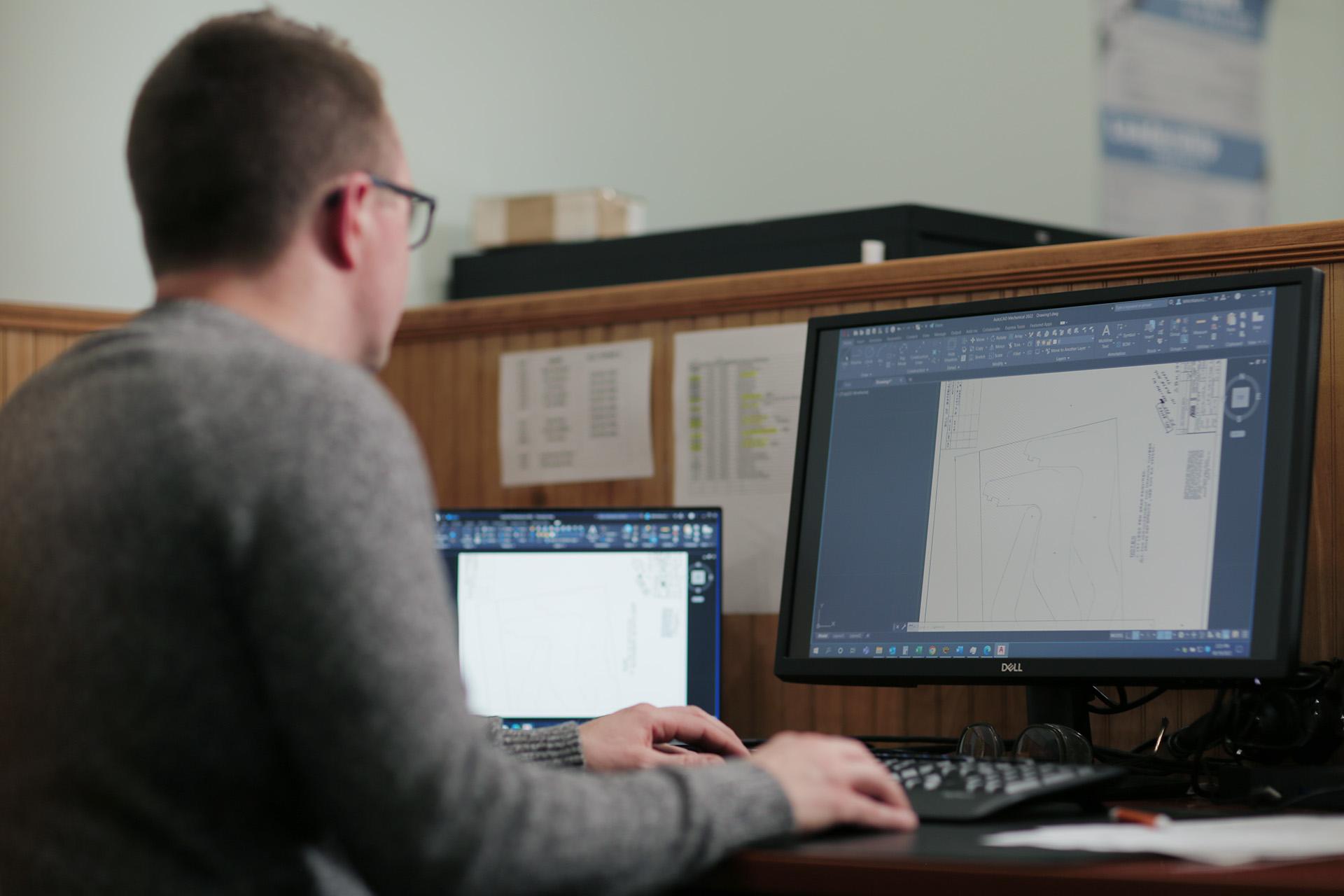

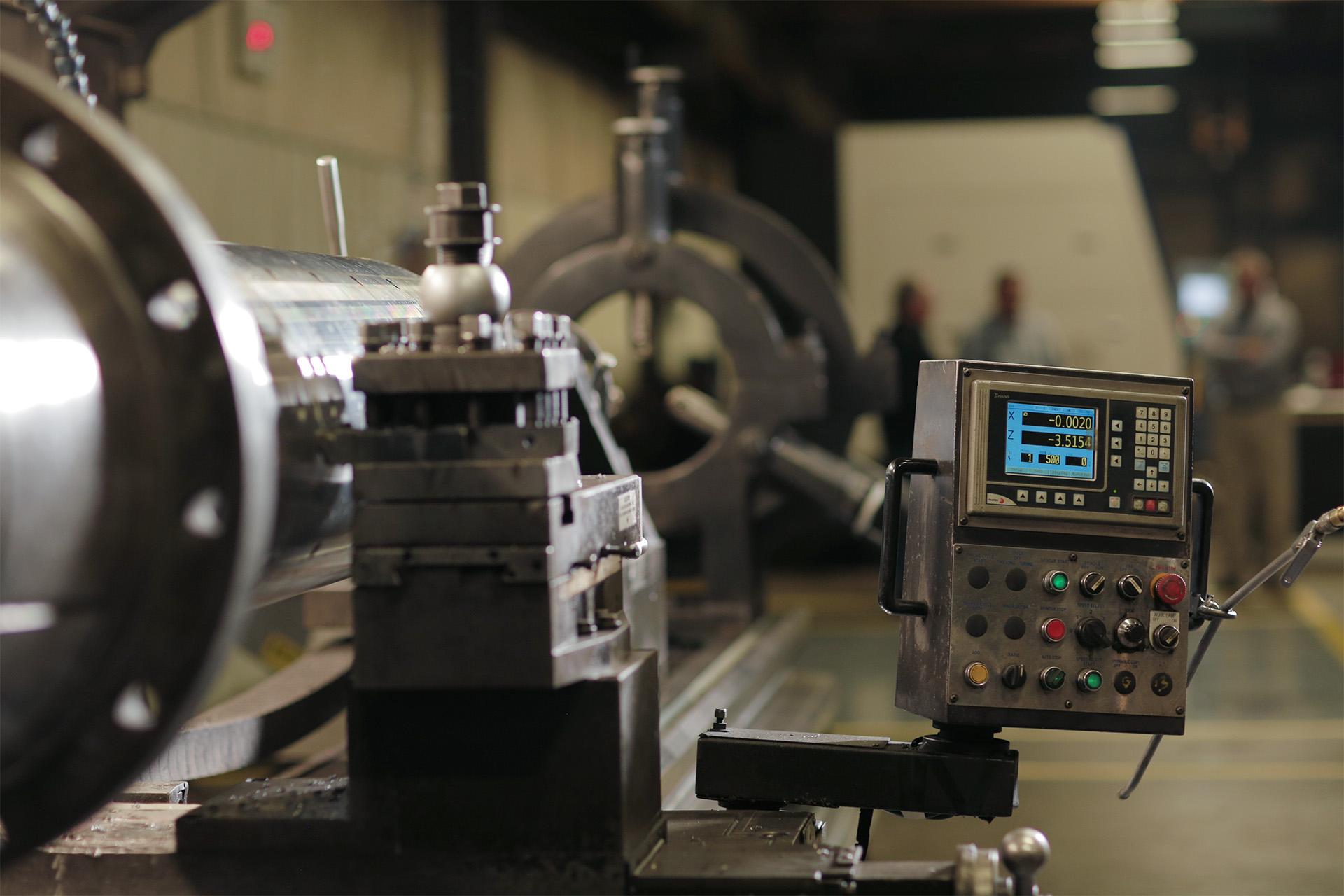

To keep your production in motion, it takes an experienced partner dedicated to your equipment 24/7. For over 100 years, our skilled team has managed the lifecycle of heavy equipment through repairing, remanufacturing, and modernizing. With expertise that spans a variety of industries—including metal stamping, forming, pressing and forging, as well as steel, aluminum and other manufactured metal production—we’re ready to help you reduce down-time in no-time.

Get to know us.